Innovations

Redclaw Hatchery

In 2004 we were the first in Australia to trial a crayfish egg incubator on an Australian species and to start a commercial redclaw hatchery. We currently have three egg incubators in our hatchery and an “out of season spawning facility” to supply eggs to the hatchery. To read more about the history of the egg incubator click here for a PDF article from Austasia Aquaculture.

There are so many reasons why egg incubation is useful, but in brief the incubator allows us to incubate eggs independently of the mother. The eggs can be cleaned prior to incubation and many pathogens are removed, resulting in increased survival and better grow rates as the craylings produced have an exceptional good health status.

This was as tested and confirmed by Associate Professor Leigh Owens of James Cook University Head, Microbiology and Immunology:

“This is a brief letter to convey to you the startling results in the improvement of the health of your crayfish that have been raised from eggs in your hatchery and then moved to various farms for grow-out. In short, it is a remarkable improvement. Across all three farms, all three viruses fell to zero; Psorospermium levels were also at zero…..”

Craylings of the same age can be stocked into a pond in one go which results in less size variation at the end of grow-out.

Grow-out trials of 2 day old craylings (weight = 0.02 grams) from the incubators conducted as part of an AgriFutures funded project produced some pretty good results. 20 000 craylings were grown for 6 weeks in 8 juvenile ponds. The results showed around 70% survival and average weight of 2 grams, that’s a 100-fold weight increase

Breeding occurs in our spawning system from mid-winter and the eggs from berried females (mothers with eggs) are stripped and either incubated to crayling in our hatchery or are cleaned and sent to other hatcheries for incubation.

Crayling is a term coined by us for the first post larval stage. It was necessary for clarity to make the distinction between them and the more common and older juveniles. Craylings are about 8 – 9 mm long and weigh less than 0.02 grams. This is the life stage when they are ready to leave the mother’s tail and begin their own independent life.

The incubation process takes about 6 weeks and the whole process from breeding till market size (about 70 to 200 grams) takes about 12 months.

Advantages of using craylings (in a nutshell):

• control over life cycle

• disease mitigation (viral, fungal, bacterial & protozoan)

• genetic improvements

• Farmers can stock known age & quantities (predict eventual production)

• improved husbandry (known bio-mass)

• extend production season

• faster & more even growth

Out of Season Spawning

We utilise an “out of season spawning facility to induce spawning. This allows us to pass broodstock from farm ponds through our spawning facility to produce eggs for hatcheries. It consists of an insulated shed containing 10 tanks totalling 120 sqm in a recirculation system. It works by manipulating temperature and the day/night photo period to condition the redclaw into thinking spring is coming and encouraging them to spawn. The eggs are then removed and taken into our hatchery to incubate or to sell on to other hatcheries.

Having over 3000 females and 1000 males of brood stock in our spawning tanks at any one time and at our finger tips has provided a wonderful opportunity to make direct observations and investigations. This has proven to be a bonanza for understanding redclaw habits and behaviours, helping us to understand and improve many aspects of redclaw farming.

This system also gives us the ability to manage genetic for growth to a higher degree than pond-based breeding. The broodstock was initially sourced from the NQCFA Selective breeding program that we were involved with.

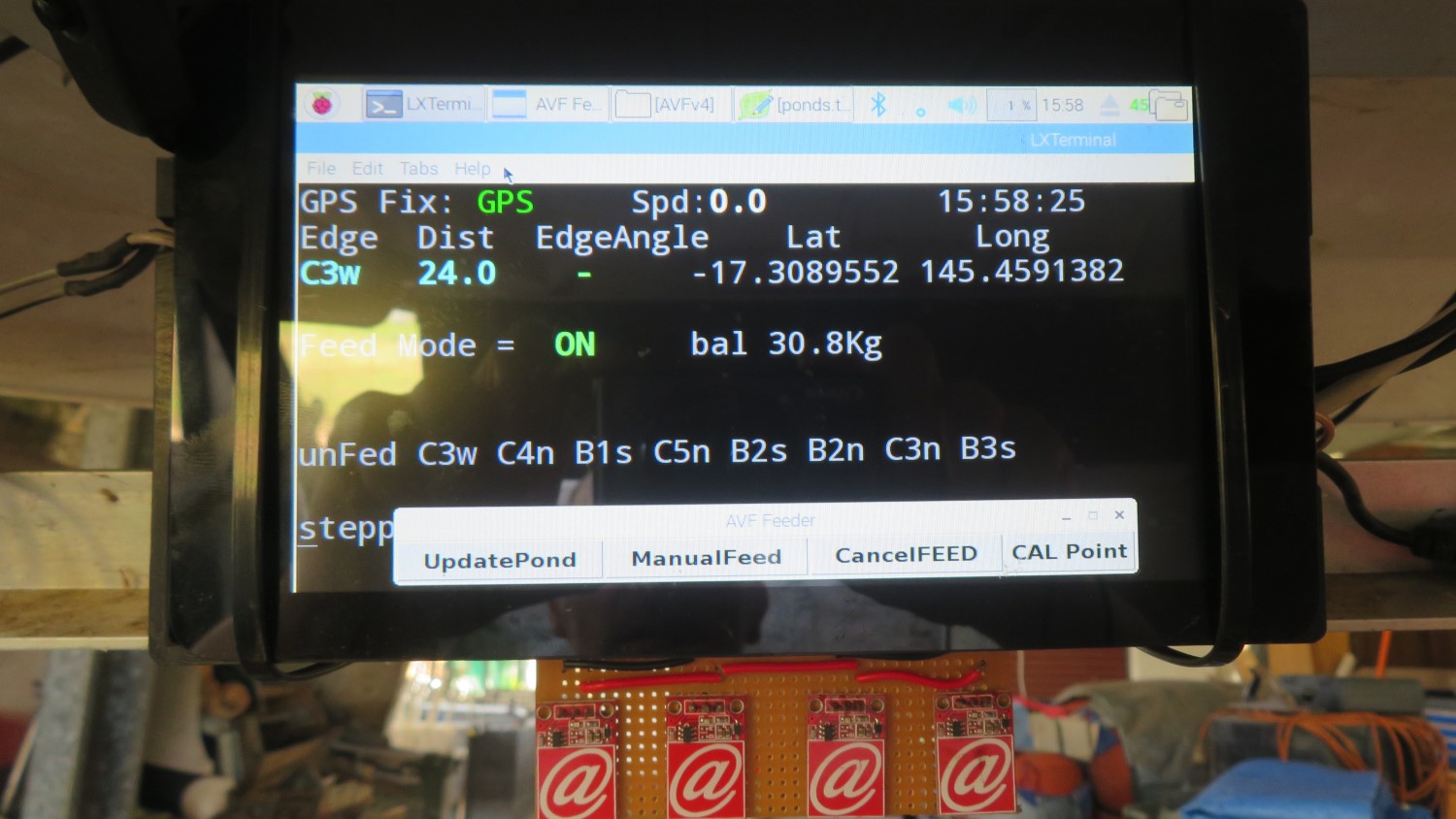

Automated Feeder

It used to take us nearly two hours each day to feed our farm by hand; walking around in the hot sun or rain with heavy buckets. There has got to be a better way! Some great input from Bill Keast formally from Ironbark Redclaw lead us to utilising an electric golf buggy, a Raspberry Pi (look it up) a GPS module, a stepper motor, an electric powered feed accelerator/spinner (custom built) and some Python programming code to make an automated feeder.

Basically, we defined a digital model of our farm by using a RTK GPS to define waypoints with centimetre accuracy. By simply driving around the farm the Pi can calculate our position, direction and speed to determine which pond side we are currently next to. It utilises look-up tables to determine if and how much to feed this side of a pond. The stepper motor is used to control the amount of feed into the spinning feed accelerator to distribute feed into the pond. Simple, right? Well not exactly, apart from the engineering it’s a surprisingly complex logic problem to solve. But we are pretty much there. I say “pretty much there” because you never actually finish a project like this, you always keep finding new refinements and features to add and even more difficult, to find the time to implement them.

The next big step would be to make the feeder driverless, basically a robotic feeder. Don’t know if we have the skills to do that, but if we are going to then I’ll need to work with Bill to make that happen. And, to be honest, I don’t know how useful a fully automated driverless feeder would really be (probably more trouble than it’s worth); but you have to admit, it would be pretty cool!

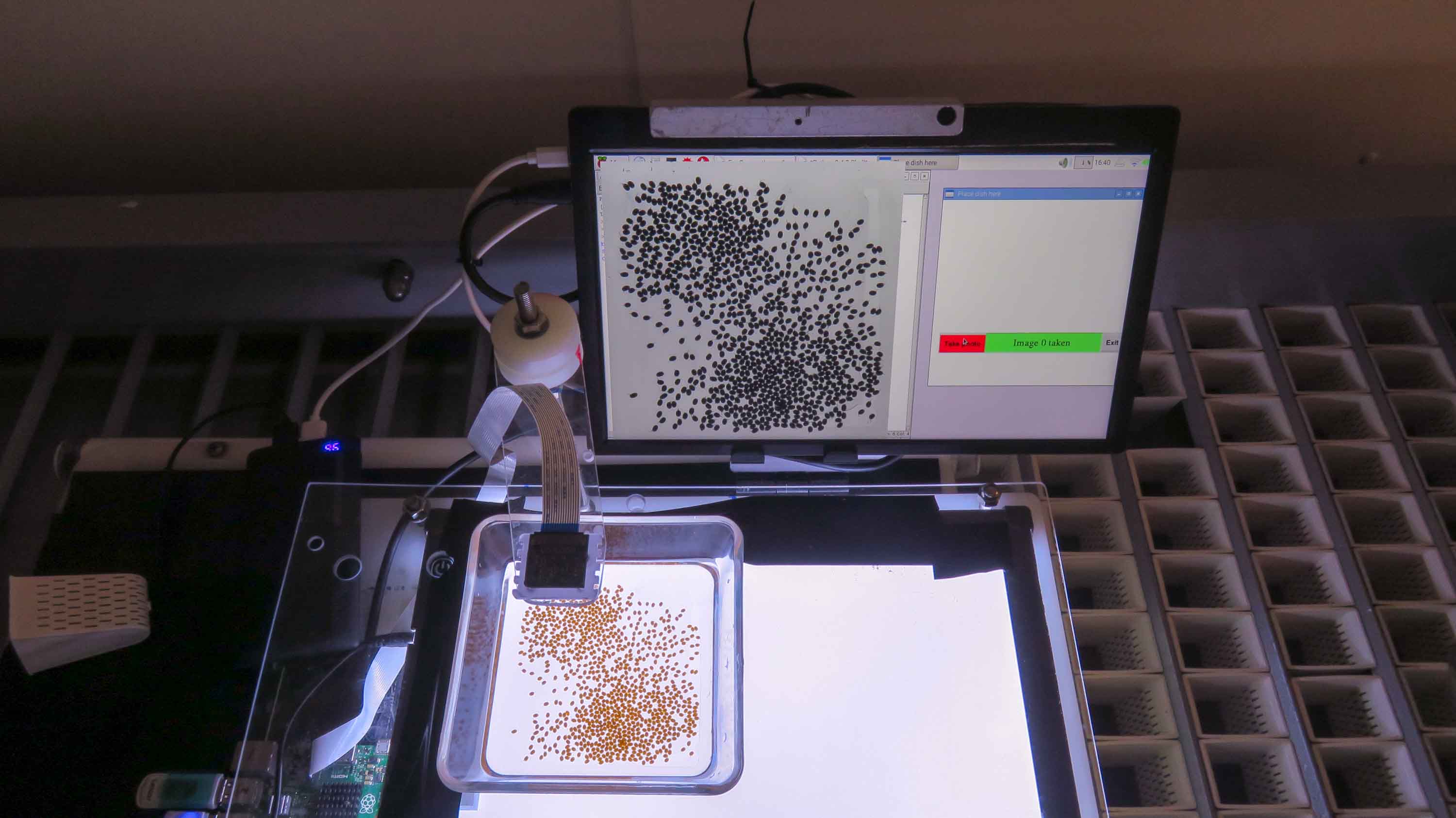

Egg counter

Another problem we needed to solve was how to count redclaw eggs. As a supplier of eggs of improved genetics to other redclaw hatcheries we needed to accurately count them.

All the commercial software didn’t really do what we needed, were too expensive and not as accurate as we needed. Redclaw eggs can have a wide range of colours, sizes and textures. Commercial counting software continually needed adjusting and tuning to get accurate counts.

So again, enter a Raspberry Pi computer, connect it to a little camera, an illuminated table and some home developed python and C codes and you have your own egg counter. We can get around 99% accuracy and are determined to improve on this result.

Once our incubators are stocked, we can systematically take photos of eggs from each basket and store it for later processing. Once photos of all eggs have been taken, an algorithm (improved by our son Nicolas) is started that goes through each photo, processes the image, counts and totals. Each day as we remove unviable eggs, we can photograph these too. They are counted and used for our statistics.

Apart from using it as a commercial tool to calculate egg totals we have began using this to understand breeding cycles, egg development, production quantities and mortalities. We hope to publish some of our findings soon.

Nursery Phase

Some of the research in this area is being done by us on our property and in conjunction with JCU Cairns by Damian Rigg under the supervision of Clive Jones. The aim is to help develop and learn about husbandry practices for craylings with the ultimate goal of implementing a high-density nursery specifically tailored to the requirements of craylings. We envisage a day when each farm will implement their own nursery facility ready to accept craylings from hatcheries. Exactly how the nursery system will look like is still being hotly debated and experimented on. But what is clear is that such a system would be a huge benefit. It will allow farmers to overlap production i.e. the redclaw in large grow-out ponds can keep growing while the craylings gain some size and weigh in a separate specialised system tailored to their needs.

Craylings can be delivered very cheaply in much greater numbers with excellent transport survival to farmers as compared to the old way of buying advanced juveniles or broodstock. They can then be stocked into an on-farm nursery for 6 weeks to grow to around 2 grams. Small purpose-built nursery ponds might have a harvest pit and are enclosed for warmth & predators protection.

We don’t know the exact nature of how a nursery system would look like yet. However we know that craylings in tanks have a slower growth rate and poorer survival than in earth ponds; but we also need the total control that tanks can offer. So, is the solution some type of hybrid system between earth ponds and tanks?

The holy grail of redclaw farming would be to spawn red claw eggs in the middle of winter, incubate the eggs to craylings and stock them into a on-farm warmed nursery system to grow to around 2 grams. Then transfer juveniles into grow-out ponds at a time when the outdoor ponds are just beginning to get the spring warmth. At that time females in outdoor ponds would only be thinking about spawning naturally and we already have 2-gram juveniles! All this overlap of production would extend the grow-out season by as much as 3 months!

Well, that’s the dream, but we believe with the work that’s recently been done within our industry we can make it happen.